Driving technology innovation for a net zero industrial future

There is a faster route to net zero

Technology

Development

We are co-investing and collaborating with industry and government to develop and deploy new technologies.

Technology

Services

Our advisory solutions help you decarbonise assets, and make the right technology investment decisions.

Start-up

Accelerator

We are propelling clean energy start-ups to commercialisation and beyond through our TechX programmes.

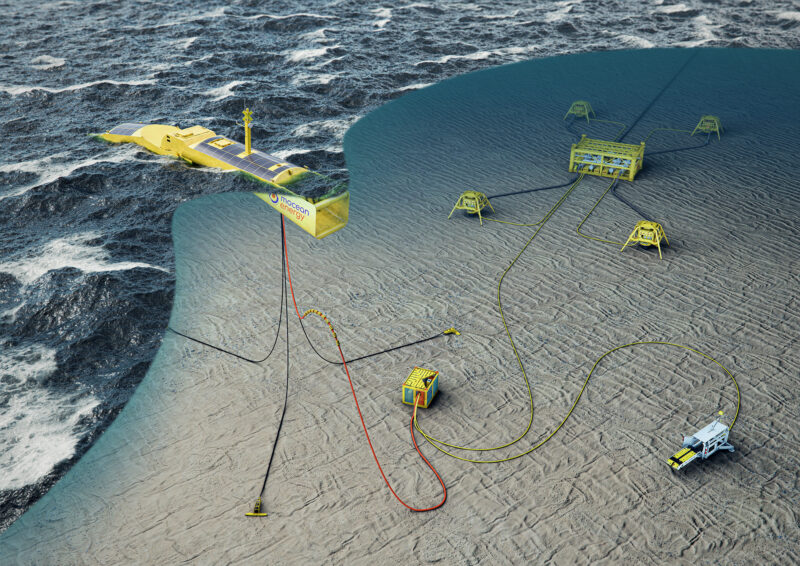

Closing the gap in net zero technology

3,130+

Technologies screened

175+

Field trials complete, planned or underway

35

Technologies commercialised

57

Start-ups accelerated